Expansion Joint Fire Barriers: Essential for Building Safety and Code Compliance

Fire protection is a critical part of any building design and expansion joint fire barriers play an essential role in that system. Architects must integrate these barriers to ensure occupancy safety and comply with modern construction codes.

In the event of a fire, these fire barriers critically prevent the spread of flames and smoke through structural gaps.

What is an Expansion Joint Fire Barrier?

Expansion joints are essential components of a building that prevent cracking or structural damage due to natural shifts. However, because these joints interrupt fire-rated walls, floors and ceilings, they can potentially create paths for fire, smoke and heat to spread.

Expansion joint fire barriers are installed within or behind the joint covers to fill gaps, maintain fire resistance and allow the joint to move freely. They’re built from materials that can both expand under high-temperature fire conditions and compress or elongate during normal, everyday structural shifts.

When specified and installed correctly, expansion joint fire barriers provide a continuous line of defense against fire at the building’s most vulnerable points.

The Role of Expansion Joint Fire Barriers in Building Safety

Fire barriers for expansion joints are one of the most important fire protection elements in the construction of a building. Let’s take a closer look at why.

Preventing Fire Spread

Without expansion joint fire barriers, the joints of a building become unprotected pathways where fire, smoke and hot gases can rapidly spread. Fire barriers seal the joint with fire-resistive materials that can expand, compress (contract) and stay in place during a fire event.

Fire barriers also play a critical role in compartmentalization. By containing fire in its point of origin, the barriers can help protect nearby areas, keep escape routes safe and limit structural damage.

In high-rise buildings, hospitals and large commercial complexes, where fire-rated separations are essential for code compliance and occupant safety, failing to properly protect expansion joints can result in total system failure.

When properly specified and installed, these fire barriers help to stop fire from jumping from one section of a building to another.

Fire Protection in Critical Areas

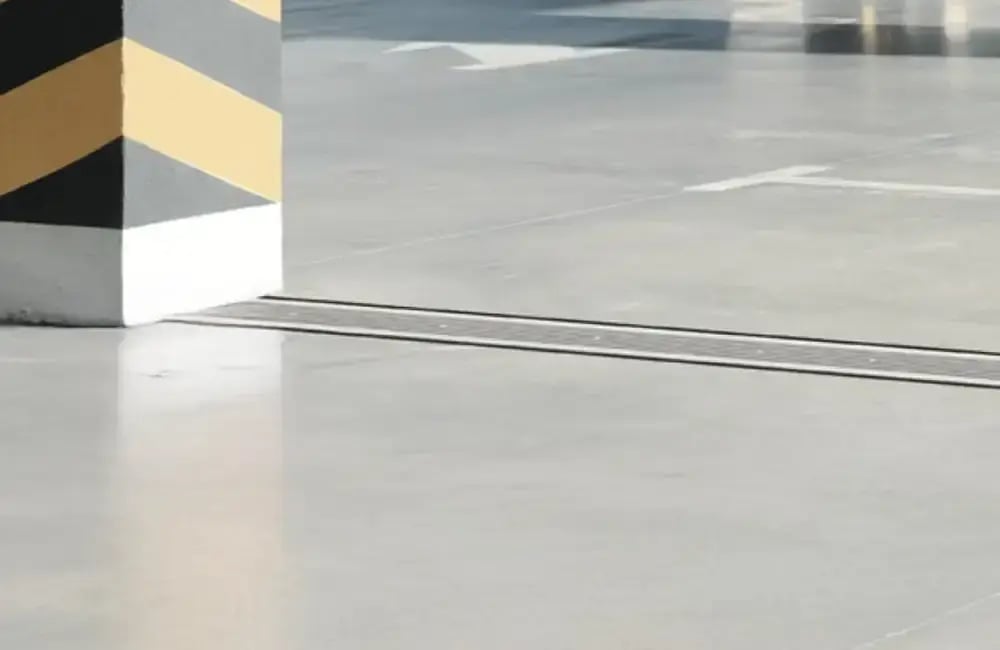

Expansion joint fire barriers are necessary anywhere that has to allow for structural movement, like perimeter walls, parking structures and evacuation pathways.

Protecting perimeter joints is challenging because they span multiple floors and meet curtain walls or other non-rated assemblies. Without proper barriers, fire and smoke can travel through these joints and spread vertically.

In parking structures, where movement and temperature changes are constant, expansion joint systems must maintain reliable fire protection.

Fire barriers are also critical for emergency pathways like corridors, stairwells and exits to ensure safe evacuation and firefighter access. Likewise, high-traffic areas like lobbies and atriums need fire barriers that buy valuable time for safe exit and emergency response.

How Expansion Joint Fire Barriers Integrate with Building Codes

Building codes are very specific about fire protection in commercial buildings. Any fire protection barriers must meet local, national and sometimes international building fire safety codes.

Code Requirements and Fire Safety

The International Building Code states that expansion joint fire barriers must be used in the construction of a building. Specifically, the 2021 IBC edition, Chapter 7, Section 715 says:

“Joints installed in or between fire‑resistance‑rated walls, floor or floor/ceiling assemblies and roofs or roof/ceiling assemblies shall be protected by an approved fire‑resistant joint system designed to resist the passage of fire for a time period not less than the required fire‑resistance rating of the wall, floor or roof/ceiling assembly.”

The National Fire Protection Association Codes and Standards also outline fire safety standards that architects and contractors must meet, such as the need for listed or approved expansion joints where building movement may compromise fire‑resistance or sprinkler integrity.

Architects must also verify that joint systems and associated fire‑barrier assemblies meet NFPA expectations for listing, testing and performance in the context of fire compartmentation, smoke control and egress protection.

Fire Protection in Egress Pathways and Parking Garages

Fire-rated systems, including expansion joint fire barriers, are required by code in evacuation routes and some parking garages to keep people safe during a fire.

In corridors, stairwells and other escape routes, they help create protected pathways for evacuation. In multi-level parking garages, fire-rated expansion joints stop fire and smoke from spreading between floors or into nearby spaces.

The IBC and local codes require these systems to meet the same fire-resistance standards as commercial buildings to ensure occupants have safe, clear exit routes.

How Codes Drive Fire Barrier Solutions

Expansion joint fire barriers and sealants must be made from code-compliant fire-resistant materials that can handle both structural movement and temperature changes. Each component must be part of a tested and listed assembly that matches the required fire-resistance rating and anticipated joint movement.

Building codes, especially the IBC, directly shape how fire barrier systems are designed.

Best Practices for Installing Expansion Joint Fire Barriers

Proper installation of expansion joint fire barriers ensures the joint system meets all fire and building code requirements while allowing the joints to function as intended and absorb building movement effectively.

Material Selection

Fire barrier systems often combine intumescent sealants that expand under heat, fireproof backer rods that provide insulation and support and metallic or elastomeric covers that protect the joint while allowing for movement.

Material selection should be based on performance specs and compliance with ASTM E1966 or UL 2079 standards.

Sealing and Fireproofing Expansion Joints

The next step is to follow the manufacturer’s instructions precisely, including orientation, anchoring and compression requirements. Specifically:

- Install fire barriers before joint covers or finishes, without stretching or altering them.

- Use clean, pre-measured openings to ensure alignment and material compatibility.

- Seal all interfaces, especially at walls, floors and transitions, with approved fire-rated materials, never non-rated foam or caulk.

- Inspect and document each phase to confirm proper installation and fire rating compliance.

Maintenance and Inspection of Expansion Joint Fire Barriers

Regular inspections and maintenance of expansion joint fire barriers are necessary to ensure that the fire barriers remain in good shape and function as intended.

Regular Inspections

Over time, building movement, wear and tear or environmental exposure can compromise the performance of fire-rated joint systems. These external factors can cause dislodgement, degradation or gaps that compromise the fire barriers.

Regular inspections should be performed in critical zones like parking structures, egress routes and perimeter joints. Identifying and addressing damage or improper modifications early helps prevent system failure in the event of a fire and reduces the risk of costly retrofits later.

Repairs and Replacements

Any fire barrier repair must use components that are part of a tested and listed system. The system must match the original assembly’s rating, movement capability and material compatibility.

Field modifications or substitutions with non-rated materials can void the system's certification and compromise the safety of the building and its occupants.

Before starting an expansion joint fire barrier repair, you should assess the extent of the damage, consult the original system specifications and coordinate with the manufacturer for approved repair procedures.

All repair work that’s done should be documented and inspected to avoid liability and maintain code compliance.

For Fire Prevention and The Best Quality In The Industry, Choose Nystrom

At Nystrom, we take pride in being a trusted industry leader in expansion joint technology — known for our commitment to quality, performance, and innovation. Our expansion joint systems deliver proven performance, innovative design and code-compliant protection for every project.

Ready to start your next project with complete confidence in fire safety and code compliance? Explore our high-performing products or contact our team to get solution recommendations for your upcoming build.