Exploring the 3 Methods for Fire-Rated Expansion Joints

Ensuring Fire Safety & Structural Integrity

Expansion joints play a crucial role in most commercial buildings, as they are essential for accommodating the expected movements caused by various factors such as thermal changes, wind sway, and seismic events.

These joints act as a buffer, allowing the building to expand and contract without causing structural damage. However, when these joints are located in fire-rated floors or walls, it is imperative to use a product or system that is rated to the same level of fire resistance.

Building codes and safety standards require that fire-rated expansion joint assemblies in fire-rated areas (e.g., 2-hour rated floor assemblies) must be tested by accredited agencies, such as UL or Intertek Warnock-Hersey, following test standards like ASTM E-1966 or UL 2079. This ensures that the materials used can withstand fire without compromising the building's integrity.

3 Methods for Achieving Fire Resistance in Expansion Joints

There are three primary methods commonly employed to achieve the required fire rating for expansion joints:

-

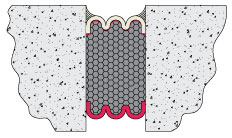

Pre-Compressed Seals with Intumescent Coating

Pre-compressed seals with an integrated intumescent coating represent the latest advancement in providing fire ratings for joints. These innovative systems are specifically designed for joints measuring 6 inches or less. They offer the remarkable capability of accommodating up to 50% movement in both compression and extension.

Pre-compressed seals with an integrated intumescent coating represent the latest advancement in providing fire ratings for joints. These innovative systems are specifically designed for joints measuring 6 inches or less. They offer the remarkable capability of accommodating up to 50% movement in both compression and extension. These fire-rated expansion joints can be installed in horizontal or vertical applications and can be concealed behind a metal cover plate. Apart from their fire-resistant properties, they also provide a watertight seal, adding an extra layer of protection. Additionally, their silicone face can be customized and colored to match the desired aesthetic of the project, enhancing the overall visual appeal.

-

Ceramic Fiber Blanket Fire Barriers

Another effective method for achieving fire-rated expansion joints is the use of ceramic fiber blankets. These fire barrier systems utilize draped or compressed ceramic fiber blankets to achieve fire ratings for expansion joints. They are capable of handling joints with larger dimensions, extending up to 32 inches. They possess an excellent range of motion capabilities, ensuring flexibility in accommodating building movements.

Similar to the previous method, these systems can be installed in both horizontal and vertical applications, although they typically require a metal cover plate to achieve the desired fire rating. The ceramic fiber blankets employed in these systems provide effective insulation and fire resistance, enhancing the overall safety of the structure.

-

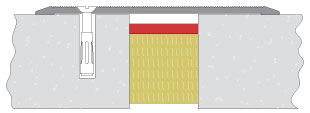

Mineral Wool Fire Barriers

The third method involves using rated mineral wool products compressed into the joint, which are then covered with a sealant to form a fire barrier (Type 3). This particular approach is commonly employed for smaller joints, typically measuring 4 inches or less, which have a limited range of motion.

The third method involves using rated mineral wool products compressed into the joint, which are then covered with a sealant to form a fire barrier (Type 3). This particular approach is commonly employed for smaller joints, typically measuring 4 inches or less, which have a limited range of motion.You will often find these fire-rated joints used in floor assemblies, where their compact size is advantageous. When properly compressed into the joint, the rated mineral wool serves as an effective barrier against fire, and the sealant applied on top provides an additional layer of protection.

Meeting Fire Safety and Building Movement Requirements

By employing these fire-rated expansion joint systems, commercial buildings can ensure both structural integrity and fire safety. These systems not only accommodate the building's movements but also meet the stringent requirements for fire resistance.

The testing procedures conducted by accredited agencies guarantee that the expansion joint assemblies conform to the necessary standards and regulations, instilling confidence in their performance during potential fire incidents.

In most commercial buildings expansion joints are a fact of life. These joints are necessary to accommodate expected building movements due to thermal changes, wind sway and differential movement typically caused by seismic events. When these joints occur in a fire-rated floor or wall, a product or system that has been rated to that same level must be used.

This means if the joint occurs in a 2-hour rated floor assembly the expansion joint system used to fill the joint must also be rated for 2 hours. Per current building codes, these joint assemblies must be tested at an accredited testing agency such as UL or Intertek Warnock-Hersey and be tested in accordance with ASTM E-1966 or UL 2079 test standards.

Nystrom understands the complexities of building expansion joints and seals. Please visit our website for more information or contact our team for help on your next project.