Seismic Expansion Joints and Multi-Directional Movement: Design Considerations

One fundamental fact in construction is that the ground is always shifting. Modern architecture is designed to adapt and move along with these changes — that’s where seismic expansion joints enter the picture.

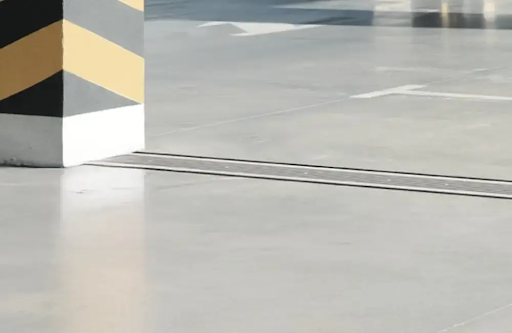

Seismic expansion joints are integrated into a building’s design to absorb complex, multidirectional movement during earthquakes and other dynamic movements. They play a vital role in keeping buildings safe, resilient and operational for the long term.

What are Seismic and Multi-Directional Expansion Joints?

Seismic expansion joints are specialized joint systems designed for buildings in areas subject to complex, multidirectional movement. These include:

- Seismically Active Regions

- Coastal and Riverfront Areas

- Expansive Clay Soils

- Permafrost and Freeze-Thaw Zones

- Mining Landscapes

- Wind-Exposed or Hurricane-Prone Areas

Unlike standard expansion joints, which handle predictable, one-directional movement from temperature changes, seismic joints are built to absorb sudden shifts in multiple directions. This flexibility protects a building’s structure when earthquakes, strong winds or other dynamic forces put heavy stress on the connections.

This makes seismic joints more complex than standard ones. While regular joints may only move along a single axis, seismic joints must stretch, compress and flex in several directions, all while remaining watertight, fire-resistant and fully capable of transferring structural loads.

It’s critically important that project teams understand the differences between seismic and standard expansion joints, as they are key to meeting code requirements and creating structures that remain safe and functional.

Key Design Considerations

When designing a new building with seismic expansion joints, it’s important to understand multi-directional movement and its impact.

Defining Multi-Directional Movements

Multi-directional movement describes a structure’s ability to shift in multiple directions at the same time. A clear example is how a building sways sideways and shifts up and down during an earthquake.

Unpredictability and Clearance

Designing for seismic expansion joints can be a challenge. It’s not easy to account for the scale and unpredictability of natural events, but it’s essential to anticipate these forces early on in the design process.

Seismic displacements are sudden, large and multi-axial, so joints must be engineered to absorb these extreme shifts. This requires coordination between design and construction to ensure joints provide enough clearance for movement while fitting seamlessly into the building design.

Successful seismic expansion joints must also find a balance between strength and flexibility. Too rigid, and they may fail under seismic stress. Too loose, and they could cause leaks, damage or safety risks.

Design and Sizing Factors

This is where material selection and joint sizing become critical. Seismic expansion joints used in areas with heavy seismic activity should be made from advanced elastomers, metals or composite systems that can stretch and compress repeatedly without fatigue.

They must be able to flex laterally, vertically and even diagonally without creating stress points that could damage surrounding components.

Meanwhile, oversized or undersized joints both pose risks. If the joint is too small, it may lock up under displacement. If it’s too large, the joint may look out of place, allow water infiltration or compromise the building’s fire resistance.

Getting these balances right requires careful coordination between structural needs and architectural finishes so the building remains safe while maintaining performance and style.

Structural Design Challenges

One of the great technical design challenges for seismic expansion joints is their integration with other key building systems. The expansion joints must fit seamlessly with structural steel, concrete slabs and cladding systems. At the same time, they need to accommodate the large and unpredictable movements that occur during earthquakes.

In addition to the structural fit, the continuity of the building envelope systems adds another challenge. Expansion joints must maintain waterproofing, air barriers and thermal insulation even as they shift during a seismic event.

Achieving this requires specialized joint covers, sealants and membranes that can flex without tearing or losing adhesion.

For project teams, the goal is to deliver a joint system that performs under seismic stress while still meeting long-term demands for energy efficiency, moisture protection and occupant comfort.

Materials and Technology

The good news is that technological innovations are constantly changing the way that seismic expansion joints and materials are engineered and monitored.

Advanced Materials for Flexibility and Durability

Rubberized compounds are commonly used in seismic expansion joints for their ability to stretch and compress repeatedly. Polymer-based systems add another layer of resilience, offering lightweight, durable options that perform well under both seismic stress and long-term environmental exposure.

Combined, these materials form expansion joint systems that can absorb complex, multi-directional movement while maintaining structural safety.

To further enhance durability, high-performance sealants and joint covers are engineered specifically for extreme movement. These products maintain waterproofing, fire resistance and air barrier continuity even as the joint moves under seismic conditions, reducing the risk of leaks, energy loss or costly repairs.

Technological Advancements in EJ Design

Seismic expansion joint technology is evolving with the integration of smart systems and motion sensors that can track joint performance in real time.

These advances give architects and contractors immediate data on how multi-directional joints react to a building’s movements. This is an incredible opportunity to improve safety and reduce maintenance guesswork.

By combining function with intelligent monitoring, today’s expansion joint systems offer a more reliable and efficient way to ensure long-term resilience in seismic building design.

Seismic Expansion Joints: Installation Best Practices

Once a seismic expansion joint system has been incorporated into a building’s design and the right materials have been selected, it’s time to focus on installation best practices.

Professional Expertise in Expansion Joint Design

Partnering with industry professionals is essential to the successful installation of a seismic-safe expansion joint system. Their expertise ensures joints are properly designed, placed and installed to handle the stresses that a specific structure will face.

For design professionals and builders, consulting expansion joint experts early in the design process can help avoid costly mistakes later on.

Site-Specific Assessments

Every building site is different, especially underground. That’s why a site-specific assessment is critical when designing a seismic expansion joint system.

Conducting detailed site surveys and seismic risk assessments ensures the system is precisely tailored to the building’s unique environment, from local seismic activity to soil type and structural layout.

Maintenance of Seismic and Multi-Directional Expansion Joints

The last piece of the puzzle is the maintenance and monitoring of the entire system. Once you have a durable seismic expansion joint system in place, you’ll want to provide the monitoring and maintenance needed to keep it performing effectively

Routine Inspection and Monitoring

Seismic and multi-directional expansion joints require regular monitoring and inspection to stay reliable over the life of a building. Routine maintenance helps identify wear, damage or misalignment before they start to compromise performance.

Repair and Replacement Considerations

When repairing or replacing seismic and multi-directional expansion joints, one of the most important considerations is that new components always align with the original design and performance criteria.

Using incompatible materials or altering specifications can compromise the joint’s ability to handle movement.

Get Expert Advice When You Need It From Nystrom

By absorbing complex, multidirectional movement during earthquakes and other dynamic events, seismic expansion joints are essential to a building’s long-term safety, resilience and functionality.

Given their critical role, it’s important to partner with experienced professionals who specialize in designing reliable seismic expansion joint solutions.

Trust the expansion joint experts at Nystrom. With decades of industry leadership, a commitment to innovation and quality and the know-how to handle projects of any size, we’ll help turn your vision into reality.

Explore our expansion joint products or contact our team for help finding the best solution for your next build.