Types of Floor Expansion Joint Covers | Nystrom

While it may seem like a small detail in the grand scheme of construction, picking the right expansion joint covers will help ensure the building’s structural integrity.

The type of expansion joint covers you choose can be a factor in how well and how long the building performs, and understanding what to consider will help ensure you make the right choice.If installed correctly, they can prevent costly damage like cracks, warping or even full ceiling failure, making them a key component that can literally make or break your designs.

Why do Expansion Joint Covers Matter?

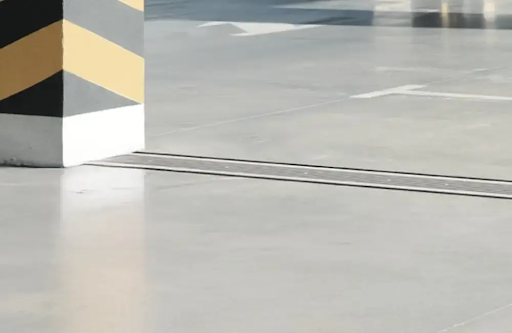

Playing an integral role in a larger expansion joint system, expansion joint covers are just what they sound like — they are covers to protect expansion joints and help ensure a seamless, safe transition across flooring surfaces in commercial and industrial buildings. These covers:

- Protect Joints: By protecting the joints from debris, moisture and fire, the covers can help prevent structural damage, contributing to long-lasting performance.

- Enhance Safety: By creating a smooth, continuous surface across the joint edges, they can reduce slip, trip and fall hazards.

- Support High-Traffic: Expansion joint covers may be designed to handle pedestrian and vehicular traffic while supporting multidirectional movement. This makes them a necessity for a range of structures, from arenas to warehouses.

Types of Floor Expansion Joint Covers Available

When choosing the right type of floor expansion covers for a particular project, professionals can choose from several different materials.

Expansion Joint Systems With Elastomeric Seals

Elastomeric seals offer flexibility, durability and noise reduction, making them ideal for environments with frequent movement and heavy foot traffic.

Because they are flexible, elastomeric seals can handle multidirectional joint movement while providing a smooth, even surface. Plus, they resist moisture and chemicals, reducing maintenance in areas prone to spills or cleaning agents.

However, elastomeric seals can wear down faster under extreme loads or continuous vehicular traffic, so this is an important consideration for commercial spaces that endure heavy and consistent traffic.

Expansion Joint Systems With Metal Joint Covers

Metal expansion joint covers provide exceptional strength and load-bearing capacity, making them perfect for both everyday use and high-traffic areas. They are also ideal for locations exposed to heavy equipment or vehicular loads, and they can be used for special applications like gym floors.

Their durability helps ensure long-term protection while maintaining a contemporary appearance that fits well in architectural designs. Many metal covers also include integrated slip resistance for added safety.

It’s important to note that metal covers may be more expensive than elastomeric seals or composite options, but their enhanced durability is worth the investment. Additionally, if these are installed in a moisture-prone area, periodic maintenance is needed to prevent corrosion.

Expansion Joint Systems With Foam Joint Covers

Foam expansion joint covers offer a lightweight, affordable option for sealing joints while allowing movement. They can conform to irregular surfaces and offer moisture resistance.

Foam covers also help absorb minor vibrations and contribute to sound reduction, making them a great choice for hospitality spaces that prioritize occupant comfort.

Aesthetic Choices for Different Spaces

Expansion joint covers can be tailored to fit the specific aesthetic of any project, including custom sizes, shapes, and finishes so that you can create a signature look or match an existing style.

Available in metal, elastomeric seals or composite materials, they can be tailored to match surrounding floors, from polished concrete and tile to hardwood and carpet.

Brushed stainless steel or anodized aluminum options provide a sleek, modern look while elastomeric seals can complement softer, more textured surfaces.

Custom color matching also allows customers to choose a solution that either blends in for a subtle effect or contrasts for a bold design statement.

By selecting the right finish and material, architects and builders can ensure that these functional elements contribute to the overall aesthetic without disrupting the visual flow of a space.

Installing Floor Expansion Joint Covers

To get the most out of your expansion joint covers, you have to install them properly.

Without the correct planning and installation, covers can be damaged or become a maintenance item, leading to frequent repairs or even replacement.

Professional Installation

The best way to make sure that expansion joint covers are installed properly is to have a professional contractor team install them.

Experienced professional installers understand material-specific requirements, building codes and best practices for durability and long-term functionality. They ensure a seamless, reliable installation that meet both structural and design requirements.

Installation Mistakes to Avoid

Common installation mistakes include:

- Improper Alignment: Misalignment of expansion joint covers can create trip hazards and maintenance issues.

- Inadequate Anchoring Techniques: This can cause covers to loosen over time, leading to premature failure.

- Failure to Accommodate Expected Joint Movement: Concrete will move over time. If installers don’t account for this, the cover can crack, break or become misaligned. This can lead to maintenance issues.

- Picking The Wrong Cover for The Building Type: Using the wrong expansion joint cover type for the application — such as a low-load option in a high-traffic area — can result in excessive wear or structural damage.

- Neglecting Manufacturer Guidelines: Not following the spacing, fastener and substrate preparation requirements can compromise durability and performance.

The best way to avoid these mistakes is to have the expansion joint covers professionally installed by an experienced team.

Ongoing Maintenance and Care

.jpg?width=428&height=295&name=unnamed%20(5).jpg)

Expansion joint covers are relatively low maintenance, but they do need some ongoing care to make sure that they last. With regular upkeep, properly installed expansion joint covers can last a decade or longer.

Regular Cleaning and Inspections

Check for debris buildup, as this can obstruct movement and cause premature damage. Also, look for signs of wear and tear or loosening of the edges of the cover.

Cleaning methods depend on the cover material — metal covers should be wiped with a non-abrasive cleaner to prevent corrosion while elastomeric seals can be cleaned with mild detergent and water.

In high-traffic areas, schedule routine maintenance to ensure the cover remains secure and functional. Address any damage or excessive wear promptly to prevent safety hazards and extend the cover’s lifespan.

When to Repair or Replace

Signs for expansion joint cover repair or replacement include visible wear, cracks, misalignment or loose fasteners that create trip hazards.

If the cover no longer sits flush with the floor, obstructs joint movement or shows excessive corrosion, it may compromise both safety and aesthetics and should be replaced.

Frequent debris accumulation or difficulty in cleaning can also indicate deterioration. In high-traffic areas, routine inspections should identify early signs of damage before they lead to structural issues.

Replacing worn or damaged covers as soon as you see them ensures the floor’s integrity, prevents expensive repairs and maintains a professional appearance.

Choosing The Right Type Of Floor Expansion Joint Cover

Expansion joint covers are required technical solutions that can make or break a design — literally.

Selecting the right covers for your expansion joints will keep them functioning properly for years to come.

At Nystrom, our floor expansion joints and joint covers are designed to help keep your building standing strong for decades. If you need help picking the best cover for your project, our experts can help.

We also offer installation and operation manuals for all of our expansion joint products, ensuring you have the right information for a seamless installation process.

Reach out to us today to discover how our products can help you build better.

Contact a Rep