Best Practices for Parking Deck Expansion Joints: Installation, Maintenance and Winter Care

Day in and day out, parking structures battle traffic, weather and wear. Keeping them strong and secure requires a layered defense — beginning with thoughtful design and extending through waterproofing, deck coatings and well-maintained expansion joint covers and seals.

When properly installed and routinely maintained, parking deck expansion joint systems protect against costly problems down the road while ensuring the deck continues to flex and move as designed.

Following best practices for installation, routine maintenance and winter care is key to keeping parking decks safe, durable and built to last.

Understanding Parking Deck Expansion Joints

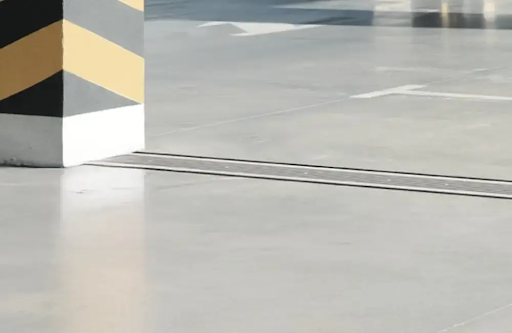

Parking deck expansion joints — engineered gaps integrated into concrete structures — are designed to absorb vertical, horizontal and rotational movement, protecting the deck from cracking, spalling and long-term structural damage.

The expansion joints absorb the natural stress and movement caused by vehicle loads, temperature swings and exposure to weather. They create a controlled space for the structure to flex and shift, which protects both the deck itself and nearby building elements.

Conveniently, expansion joints also manage water. They’re able to channel it off before it can infiltrate and damage the deck’s concrete structure. Water that seeps into a deck can rust the rebar and cause cracking or flaking, especially in decks that are tensioned after the concrete has cured (post-tensioned decks).

Well-placed expansion joints safeguard the deck’s overall performance, extending its life and reducing maintenance needs and costs.

How Parking Deck Expansion Joint Covers and Seals Accommodate Movement

The primary role of a parking deck movement joint — and its cover and seal system — is to absorb the deck’s natural expansion, contraction, daily movement and, in some cases, seismic activity.

When correctly designed, sized and installed, these systems protect the structure from stress, cracking and long-term deterioration.

Handling Movement Under Vehicular and Heavy Loads

Expansion joints are integral to parking deck performance, accommodating vertical, horizontal and rotational deck movement under constant vehicle loading. By relieving stresses from traffic, thermal cycling and potential seismic forces, they prevent structural damage and extend service life.

This constant movement leads to flexing, contraction and lateral shifts across the deck surface. Without a way to manage that stress, the deck can be exposed to issues like sinking or buckling, as well as create tripping hazards, potholes or more serious structural weaknesses down the line.

Expansion joints work like flexible buffers, allowing the deck to move in different directions while keeping the structure intact.

Best Practices for Installing Parking Deck Expansion Joint Covers and Seals

Properly installing parking deck expansion joints is essential for it to work effectively. If the expansion joints are not installed or maintained correctly, it can drastically impact how well the joints protect the concrete deck and can lead to costly repairs.

Proper Sizing and Spacing of Expansion Joints

Proper installation of expansion joint covers and seals begins with accurate sizing. These components must be selected and designed to accommodate the expected thermal movement, structural shifts and traffic loads that the parking deck will experience.

If the expansion joint cover or seal is not properly sized, it will not be able to absorb movement effectively — leading to cracking, water infiltration and potential joint system failure. A correctly sized cover or seal maintains flexibility and durability, even under continuous or heavy vehicle traffic.

While sizing is critical, proper spacing between expansion joint systems is equally important. Installing expansion joint systems too close together — or too far apart — can result in uneven stress distribution, accelerating wear on the surrounding concrete.

Appropriately spaced expansion joint systems help distribute loads uniformly and allow the structure to move as intended, increasing the overall lifespan of the parking deck.

Choosing the Right Materials for Parking Deck Expansion Joints

Selecting the right expansion joint material for your environment is a crucial decision. Foam, metal or rubber-encapsulated cover plates each offer different advantages, depending on the climate and expected traffic loads.

For example, regions with high rainfall or intense heat may require expansion joint systems that offer improved waterproofing and UV resistance.

In colder climates where heavy snow and ice are common, robust expansion joint systems are essential. While metal cover plates can handle the weight and abrasion of snowplows and heavy equipment, they may protrude above the surface and become prone to damage. In many cases, flush-mounted seals or systems designed to sit level with the deck provide a more durable solution, resisting tearing, displacement and impact while maintaining a smoother driving surface.

Ensuring Proper Sealing and Waterproofing

The sealing and waterproofing of expansion joints help keep the system watertight while protecting the structure beneath. A properly sealed joint prevents water from penetrating the slab, helping avoid cracking, corrosion of rebar and cables and weakening of the concrete.

Maintenance of Parking Deck Expansion Joints

Maintaining expansion joints is just as impactful as correct installation. Always use maintenance best practices to ensure the joints are free of damage and performing properly. It’s far easier and less expensive to do routine maintenance than to repair a damaged slab.

Routine Inspections for Wear and Tear

Wear and tear inspections should be done regularly for all expansion joints. Look for any signs of damage on the joint, cover or seal. Pay special attention to heavy-use areas near traffic pathways or those used by heavy machinery.

When inspecting an expansion joint, pay particular attention to the sealing material — look closely for any cracks or tears that could allow moisture to seep in. Rely on a specialized guide that discusses maintenance strategies to ensure proper care.

Repairing and Replacing Damaged Expansion Joints

Over time, expansion joints may require repair or replacement. However, regular maintenance and timely replacement of worn materials can significantly extend the parking deck’s lifespan and help avoid expensive repairs in the future.

Winter Care Considerations

Winter conditions put parking decks at risk due to freeze-thaw cycles, deicing chemicals and snowplow damage.

Using cold-weather joint materials, maintaining seals, inspecting regularly and careful snow removal are key to protecting the structure and extending its lifespan.

Get Expert Help On Your Next Project With Nystrom

At Nystrom, our expansion joints are built to deliver reliable performance and lasting durability in even the most extreme weather conditions.

As an industry leader, we combine smart design with cutting-edge technology to create solutions that professionals can truly count on — like our latest innovation, the Wing Seal WS System.

Engineered to maintain a watertight seal under seismic movement and low-speed traffic, our Wing Seal WS System is ideal for parking decks that face horizontal and vertical movement on a daily basis.

Check out our Wing Seal WS System, along with our extensive product line of parking deck expansion joints, to find the best solution for your next project.

You can also learn more about managing buildings with expansion joints in our live webinar courses.

Contact a Nystrom Representative