Why Concrete Floor Expansion Joints Matter

You don’t really see them, but concrete floor expansion joints are a big deal in commercial buildings. They’re one of those hidden things that keep the place solid and safe. Picking the right ones can make a huge difference in how long your floor lasts.

Here’s why they’re worth caring about.

What Concrete Floor Expansion Joints Do

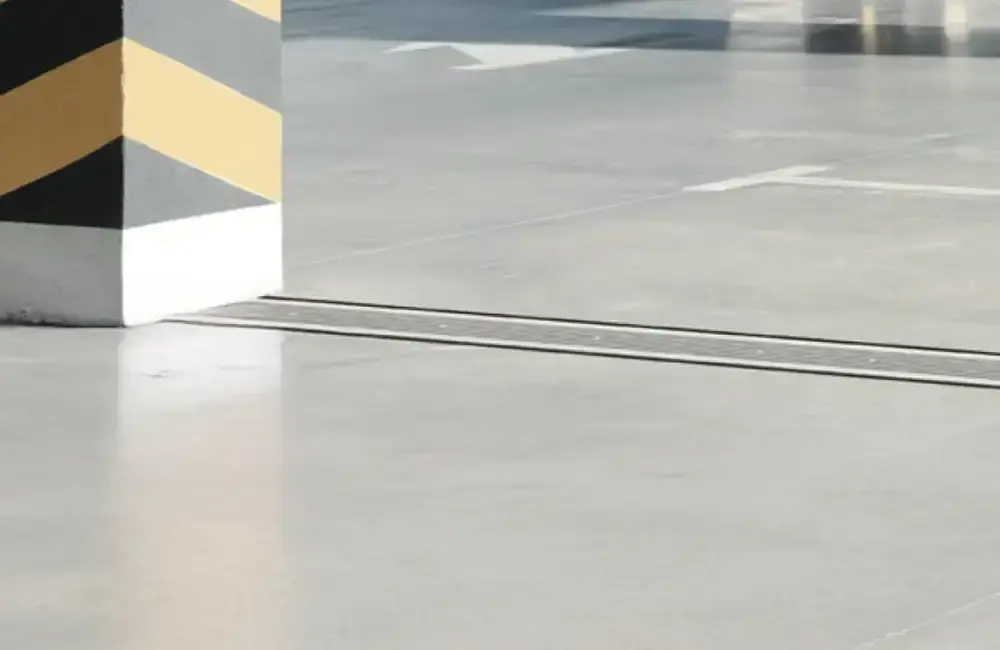

Concrete moves—expands when it’s hot, shrinks when it’s cold, shifts under weight. Expansion joints give it space to do that without cracking. They keep the floor smooth and safe for traffic, whether it’s people walking or forklifts rolling.

They also seal up gaps so water, dirt, and junk don’t get inside. Without them, that stuff can build up and mess up the floor over time.

How Concrete Floor Expansion Joints Stop Cracks

Concrete’s always shifting a little—heat, moisture, heavy loads all play a part. Expansion joints put gaps in the right spots so the slabs don’t push against each other and crack. In big buildings, they’re placed carefully to handle that movement and cut down on damage.

You might see rubber seals, fillers, or metal plates in there—they keep the joint steady while letting it flex. They also stop the floor from settling unevenly, which keeps it level for years.

Tough Enough for the Job

In places like warehouses or factories, floors get hammered by heavy use. Good expansion joints make sure they hold up without cracking or shifting. They’re a key reason those floors last so long.

One thing to watch: if the building gets busier later on, the joints might need a tweak to handle more weight. Thinking ahead saves trouble later.

What to Think About When Installing Concrete Floor Expansion Joints

It’s not just about slapping joints in. You’ve got to match them to the building—how big it is, how much traffic it gets, what the weather’s like. A 6-inch slab might need joints every 12 to 18 feet, but that can change if it’s a hot or wet area.

Materials depend on the job too. Rubber seals work great for wet spots; metal’s better for heavy traffic. Cheaper stuff might save money now, but it could cost more to fix later. For big projects, it’s smart to get a pro to install them—they’ll figure out the size and spacing so it lasts.

Keeping Concrete Floor Expansion Joints in Shape

Once they’re in, expansion joints don’t need much. Check them now and then for wear, especially the seals. Replace anything that’s breaking down, and they’ll keep going for a long time.

A Must-Have for Commercial Projects

At first glance, expansion joints don’t seem exciting, but every commercial floor needs them. They deal with movement and weight so the concrete doesn’t fall apart. Every building’s different, though—you need the right setup for yours.

At Nystrom, we’ve got people who know expansion joints inside out. We can build a system for you or check what you’ve got to make sure it’s solid. With all the options we offer, you’ll get what works best for your project.

Need help with yours? Contact us today and let’s sort out your floors.

.png)